Several types of mattress manufacturers have repeatedly shown that a lack of quality mattress edge tape can affect the long term durability of the mattress.

Mattress manufacturers and other mattress products are addressing the issue of sleep and improving the experience of getting a better night's sleep. Mattress manufacturing is a thriving and highly valued industry, and many startups are embracing it as well.

There are numerous mattress manufacturers on the market today, and it is extremely difficult to differentiate your brand in such a competitive environment. Because the composition of the mattress cannot be changed, mattress manufacturers are experimenting with mattress design to differentiate their products from the competition.

Mattress aesthetic design assists the manufacturing industry in developing a distinct identity for its brand.

Mattress design plays a very crucial role in creating a brand its identity. The two most important factors that are responsible for the mattress design:

Mattress Fabric

Mattress Tape

Mattress tape is an important part of creating a brand identity and helping the brand stand out from the crowd. Like a fashion trend is incomplete without jewellery, a mattress design is incomplete without mattress tape.

The mattress tape edge serves as jewelry for the mattress that enhances the mattress's aesthetic design. Mattress tape is used as a finishing touch in mattress design.

Types Of Mattress Tape

As a mattress manufacturer, you should be aware of the various types and ranges of mattress tape:

Mattress Woven Tape

Designer mattress tapes can be made using woven mattress tapes. Manufacturers can create one-of-a-kind designs with woven mattress tapes. Mattress woven tape is known by many different names but they all mean the same thing. Mattress woven tape is also known as mattress fabric tape, polyester mattress tape, mattress tape edge, and mattress webbing tape.

Woven mattress tape is made in the same way that textile fabric is. The warp and weft weaving technique is used to create an interwoven webbing that becomes a fabric. Mattress tape is made in the same way that any other garment fabric is made.

There are many design option available for polyester woven mattress tape. Leading Mattress manufacturing brands usually have this as a standard requirement. This helps them design a unique pattern for their mid, premium and luxury mattresses. Woven mattress tapes are used by majority established mattress makers due to its durability, quality and design range.

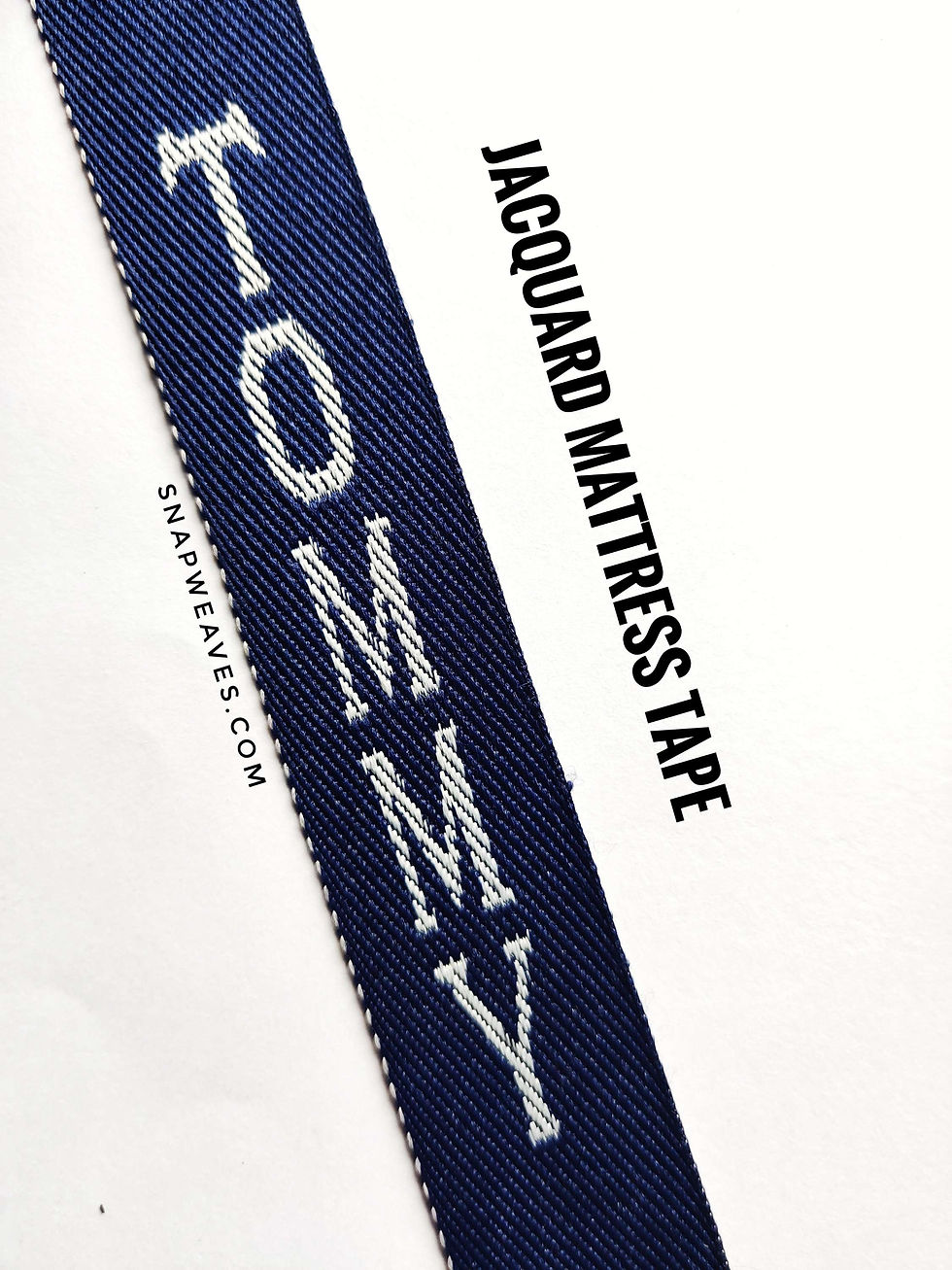

Jaquard Mattress Tape

Jaquard mattress tape is used to create intricate non-geometric designs. These tapes are used to promote brands. Jaquard weaving allows for the weaving of the logo on the mattress tape. At the same time, the cost of this type of mattress tape nearly doubles due to the lengthy and complex weaving pattern.

Jacquard Mattress Tape is being phased out in favor of printed or woven labels that cost less than 3 INR per label used per mattress.

So, if the mattress manufacturer has a large budget and wants a complex design or a logo on the mattress tape. This is the best choice. It not only assists the manufacturer in imprinting its logo on the mattress but also improves the mattress's design.

Crochet Knitted Mattress Tape

Crochet knitted mattress tapes are distinguished by their stiff foldability and consistent finish when compared to regular woven mattress tape. Crochet Mattress tape edge is ideal for bulk orders and consistent colors and designs.

For bulk production and stiff folding, this is the second-best alternative to woven tapes. However, the designs are limited to crochet knitted tape. This is used by low to mid segment to bring down the mattress tape cost.

Mattress Tape Quality Ranges

Let’s look into the quality ranges of the mattress tape:

Lower GSM Mattress Tapes

Lower GSM mattress tapes are used for mass production, low cost, and low segment markets where mattress construction and quality is of little importance. This is for mass production using only a push product strategy.

Mid-GSM Mattress Tapes

Mid-GSM quality mattress tapes are the sweet spot between premium and low-cost. Mid-segment or economy mattress manufacturers prefer Mid-GSM mattress edge tape because it is inexpensive and has a good finish. Manufacturers prefer Mid-GSM mattress tape because it fits their budget and provides a pleasing design aesthetic.

Higher GSM Mattress Tapes

If standardization of product design is important to you as a mattress manufacturer, high GSM mattress tape is your best option. Your brand's products speak for themselves. This gives your mattress a tight, flawless finish. Many leading brands prefer higher GSM mattress tape because it helps the manufacturer improve the overall design aesthetic of their mattress.

Summing Up

In conclusion, the role of mattress tape in the overall design and aesthetic appeal of a mattress cannot be overstated. It is this seemingly insignificant component that has empowered manufacturers to elevate the design and visual appeal of mattresses, thereby ensuring a superior quality product.

To truly enhance the design of a mattress, one must have a comprehensive understanding of the quality of mattress tape. Remember, the beauty of a mattress lies not just in its comfort, but also in the details - and mattress tape is a detail you can’t afford to overlook.

Comments